The front sight is typically the most well-known element of a technical drawing. The key goal of the front sight is to deliver a clear, simple representation of the item that stresses crucial attributes, dimensions, and percentages.

Building upon this, the leading sight matches the façade by offering details about the deepness of the object. This sight permits designers to see just how wide and deep the item is, removing ambiguity that might arise from the preliminary façade alone. The top view aids to visualize connections in between different aspects of the layout, making it simpler to recognize the format of elements, specifically in intricate systems with numerous overlapping components. When made use of effectively, the top view can assist connect essential aspects of performance and spatial setup that are essential for manufacturing and assembly.

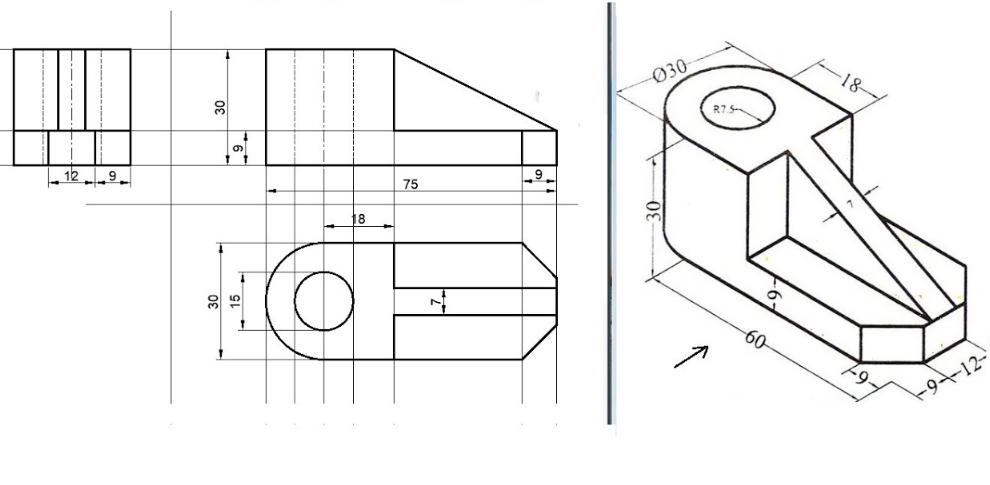

The side sight, also referred to as the profile view, uses yet an additional viewpoint by depicting the object's height and depth. It is especially beneficial for showcasing functions that might not be as obvious in the front or leading views. By including the profile into the technical drawing, designers ensure that all dimensions can be precisely provided, producing a detailed sight of the item. The side view can highlight contours, slopes, or any type of projections that may be considerable to the style's operational effectiveness and aesthetic charm.

Explore technical drawing views the important role of technical drawing in engineering and architecture, highlighting vital views such as front, top, side, area, and isometric viewpoints that make sure exact interaction and execution in design and manufacturing.

Section views are an additional essential part of technical illustrations. They supply a method to portray the internal features of a layout that could not appear from the outside views. A section view is developed by cutting with the item and exposing its internal geometry. This technique permits designers and engineers to explore complex attributes such as dental caries, shapes, and materials within a design. Consisting of section views aids to protect against complication in comprehending the design, specifically for complex assemblies where internal configurations could affect performance or manufacturability. By creating these cuts in the things, technical illustrations end up being more insightful, enabling more comprehensive assessments of how parts will certainly communicate once constructed.

Another beneficial technique in technical drawing is isometric projection. This sight uses a three-dimensional representation of the things, offering a helpful impression of depth and range without needing complex viewpoint computations. Isometric views can be incredibly helpful in communicating the total design of an object, particularly to individuals that may not be fluent in checking out technical illustrations. While isometric forecasts fall brief of representing real perspective, they continue to be a popular selection for providing concepts clearly and not surprisingly. This makes them especially useful throughout the early layout stages when comments and iterative enhancement are essential.

In addition to these essential views, there are different other kinds of estimates, such as orthographic and perspective projections, that serve different features in technical drawing. Orthographic estimates are a collection of numerous views that separately portray the item from various angles, normally in a two-dimensional layout.

To successfully create a technical drawing, it is vital to comprehend the conventions and signs that stand for various attributes and dimensions. Architects and engineers utilize different lines-- such as solid lines, rushed lines, and centerlines-- to communicate details concerning edges, features, and crucial places. Dimensioning is an additional essential part of technical drawing. Proper dimensioning provides important measurements that dictate exactly how elements mesh, making sure that styles satisfy needed resistances and specs. Unreliable measurements can bring about pricey blunders throughout production, making this facet of technical drawing critical for integrity and success.

Numerous software program devices and applications assist in the technical drawing procedure, improving the conventional hand-drawing methods. Programs like AutoCAD, SolidWorks, and other Computer-Aided Design (CAD) software permit customers to produce complex 2D and 3D designs with far greater accuracy and adaptability than hands-on methods. These tools enable easy modifications, permitting for quick prototyping and version without the requirement to recreate drawings from square one. This electronic improvement has considerably accelerated the layout and manufacturing procedures across various markets, driving innovation and boosting performance.

In the context of markets today, recognizing exactly how to apply different views in technical drawing is not just crucial for engineers and engineers yet likewise for suppliers, product developers, and even marketers. In collective environments, especially in fields like building and manufacturing, clear technical illustrations ensure that all stakeholders-- from developers to clients-- are on the exact same web page.

The ability to from detailed technical illustrations, including several views, is necessary for creating parts that not just fit with each other correctly however likewise run efficiently as part of more comprehensive systems. In addition, as industries shift to electronic and automated procedures, the abilities needed to create and translate technical illustrations will certainly be crucial to future skill pipes.

In verdict, technical drawing includes different views, each of which plays a certain function in communicating required information about an object. As technology and approaches for producing technical drawings continue to breakthrough, understanding and executing these views successfully continues to be vital. As we relocate further into an era characterized by rapid technological advancement, the concepts of technical drawing and its associated views will definitely stay important in shaping the future of layout, manufacturing, and engineering.